Sep 24, 2025

Hello Everyone!

Massimo here, writing with great excitement from inside the factory. The atmosphere at Geoship is electric, a mix of pride, pressure, and anticipation as we prepare for the release and installation of our first customer-ready home, reverently called Amma One. This milestone is the culmination of more than eight years of vision, research, and relentless iteration. What once lived only in imagination is now becoming reality, and we couldn’t be more stoked!

Working in production gives me a unique vantage point because I see the product at every stage. We’ve built and refined the process ourselves, from designing racks and molds to building prototypes, testing them, and carefully handling each ingredient, so I know the product from the inside out.

Not long ago, we were just four techs working from engineer drawings. Now, that empty warehouse has transformed into a buzzing production floor with more than a dozen people, turning out 20 to 40 parts a day. I’m excited to take you inside and share the progress!

Welcome to the GeoJourney Video Series:

With that spirit, I am proud to introduce the first episode of The GeoJourney, our new video and blog series. We will share these updates a few times each month, not only to announce milestones but to bring you closer to the people and processes that are shaping the future of regenerative living.

A Deep Dive into our "Slice Mockup" Project

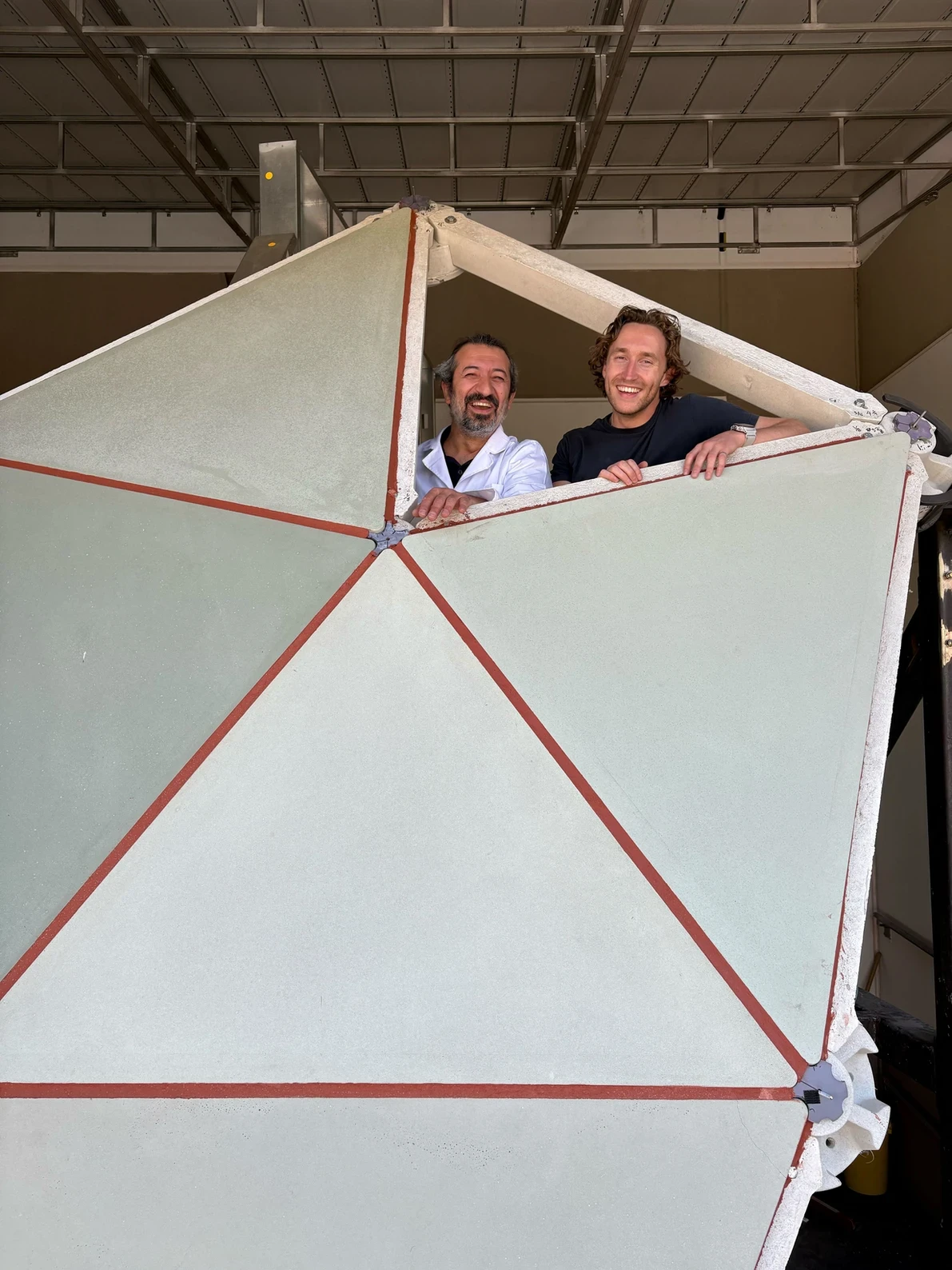

At first glance, the slice looks like just a fraction of the dome—one fourteenth, to be exact. In practice, it has become our hands-on laboratory, where our engineers and install team refine workflows, validate design choices, and test details like doors, windows, and joinery before we assemble the full structure.

Here we problem-solve in real time: Does everything fit? What tools are required for top panels? How can we simplify installation and improve the final product?

As you’ll see in the video, we’ve already used the slice to test the exterior frame, and we’ll continue building it out to refine every component and interaction.

Chemist Ali and Engineer Kyle peeking through the slice mockup

Testing That Builds Confidence

Alongside the slice, our team has been immersed in rigorous testing. Each milestone adds confidence that our domes meet the highest standards of safety and durability. Two recent examples are our fire safety certification and our snow load structural test.

Fire Safety: Non-Combustibility

In the Sierra Nevada foothills, where Geoship is based, communities live with the constant reality of wildfire risk. Our first customer dome will rise in nearby Nevada City, a community where families keep evacuation bags packed and insurance costs climb higher every year. In this environment, safety is not just about meeting codes, it is about peace of mind. This is why validating fire safety is so important for the communities we serve. Unlike wood or conventional materials, our bioceramic is truly non-combustible. It does not ignite, burn, or release flammable gases, even under extreme heat.

Non-Combustibility Test Our bioceramic material was tested under ASTM E136-19a standards, which expose it to 750°C (about 1,380°F) to measure combustibility. The results confirmed it is non-combustible: it will not ignite or burn when exposed to extreme heat.

Strength: Snow Load Testing

Our homes are also designed for durability in harsh winter conditions. To simulate twice the heaviest snowfall recorded at our Nevada City site, we built a large test rig and loaded a panel with weight far beyond what nature is likely to deliver.

The test was conducted to meet Nevada County’s heavy snow requirements, using the 50-year ground snow load standard (about a 2% chance of being exceeded in any given year) as defined by ASCE7 and supported by county case studies.

The result? No cracks. No failures. The panel flexed exactly as designed and held strong through every repetition. This means not only safer homes, but also no need to shovel roofs in winter.

A Turning Point

Every part we make and put on the slice, every test we perform, every milestone we achieve is a celebration here and they carry us forward. They are not just technical achievements, for us they are the steps that validate our life dreams for a larger transformation: we are part of the regenerative living revolution, from concept to reality and that feels amazing. How does it make you feel knowing that this is possible?

As Micha says in the video:

“This is the inflection point where vision becomes reality and where we prove that Geoship is a viable solution for our housing future. We’re taking the time to learn, refine, and improve everything about our domes with this first install so we can scale up what we are doing and bring these regenerative, climate-resilient solutions to the masses everywhere. This is the future of living, and it’s happening now.”

We look forward to bringing you along on this journey to witness not only the outcomes but also the process, the human effort, the learnings, and the dedication behind them so you can see we are just people with the right tools, the right mindset and a lot of support. Soon, our first dome will rise, and with it, a new chapter in how we live in this world.

With gratitude,

Massimo Massarotto

from the Geoship Team